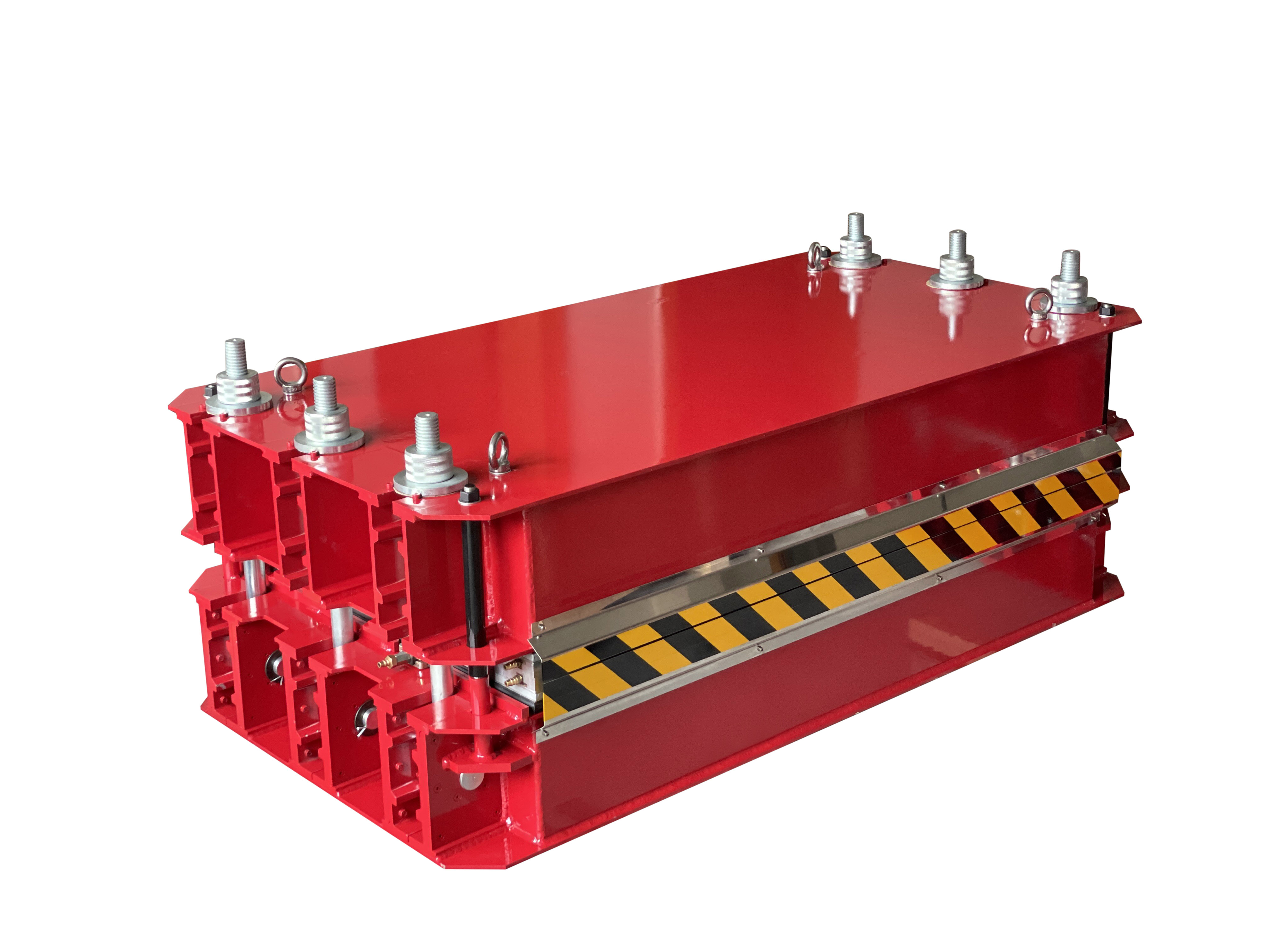

Maintenance and upkeep of belt vulcanizing machine

As a conveyor belt joint tool, the belt vulcanizer should also be maintained and maintained like other tools during and after use to extend its service life. The storage environment should be kept dry and well ventilated to avoid electrical wiring being damp due to humidity; Do not use the belt vulcanizer outdoors on rainy days to prevent water from entering the electric control box and heating plate.

If the working environment is humid and watery, when disassembling and transporting the vulcanizing machine, objects should be used to raise it on the ground, and the vulcanizing machine should not come into direct contact with water. During use, if water enters the heating plate due to improper operation, the manufacturer should be contacted for repair first. When the belt vulcanizer is not needed for a long time, the heating plate should be heated every half month (set at 100 ℃) and kept at a temperature of about half an hour.

The correct way to drain water is to do so after the vulcanization insulation is completed and before the vulcanization machine is disassembled. If water is discharged after disassembling the machine, it may cause the water in the water pressure plate to not be completely discharged. If emergency repair is required, the cover plate on the heating plate can be opened, water can be poured out first, and the electric control box can be set to manual operation. Heat it to 100 ℃, maintain a constant temperature for half an hour, dry the circuit, and perform belt bonding in manual mode.

At the same time, the manufacturer should be contacted in a timely manner for the overall replacement of the circuit. After each use, the water inside the water pressure plate should be drained thoroughly, especially in winter. If the water cannot be drained completely, it often leads to premature aging of the water pressure plate rubber and reduced service life of the water pressure plate. Wear protective equipment during operation and do not use wet gloves. Preheat the plate before vulcanization, and check whether there are sundries between the layers of the plate and whether other parts are normal.

Pressure gauges and thermometers should remain sensitive and effective, and strictly control steam pressure, oil pressure, and vulcanization temperature according to safety and process conditions. When loading the vulcanization mold, hands should not reach into the flat panel to prevent scalding and squeezing. If problems are found, the car should be stopped for handling. The molds used should be placed smoothly to prevent falling and injuring. After the operation is completed, cut off the power supply, close the water and gas valves, and return the mold to the designated location.

英语

英语 英语

英语