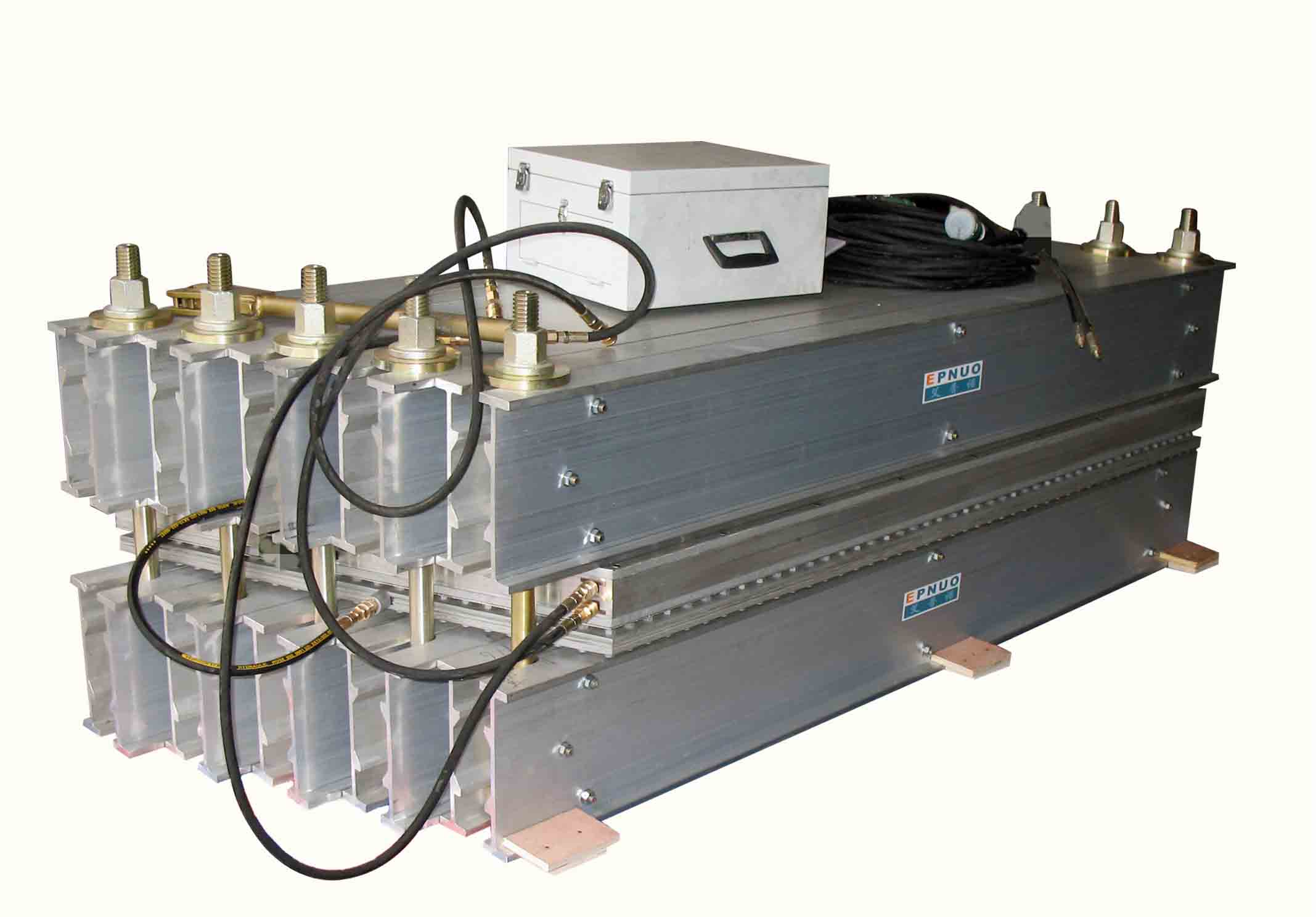

Briefly tell you the characteristics of the upper and lower heating plates of the belt curing press

1. The upper and lower heating plates of the curing press are small in size, half in weight, low in energy consumption and fast in temperature rise. After heating, the whole plate surface is quite flexible, which is closer to the tape than that of the conventional press,

Under the pressure of 1.5 mpa, its parallel tightness is not more than 0.03 mm, which is not available for conventional machines.

2. The upper and lower heating plates of the curing press provide heat evenly. After entering the heat preservation stage for 10 minutes, the temperature difference at each point of the working face is only ± 3 ℃~4 ℃, which exceeds the international standard.

3. The time from normal temperature to vulcanization temperature (145 ℃) shall not exceed 25min, the power is half lower than that of the same industry at home and abroad, and the energy saving effect is good.

4. Vulcanized rubber joint or repair shall be formed at one time, and the bonding part shall be flat and smooth, with the same fastness as the original belt.

5. The upper and lower heating plates of the curing press are trinity, with simple structure and easy installation. The five advantages of the upper and lower heating plates of the curing press are incomparable to other machines.

英语

英语 英语

英语