What are the precautions before using the conveyor belt vulcanizer?

Before using the conveyor belt vulcanizing machine, the insulation resistance of the hot plate should be checked. If it is too low, it should be dried with electricity first until the insulation value reaches below 50MPa before use. During the use and transportation process, it should be handled with care and handled in a civilized manner. If working in the field, reliable rainproof and waterproof measures are required to avoid being affected by rain and moisture.

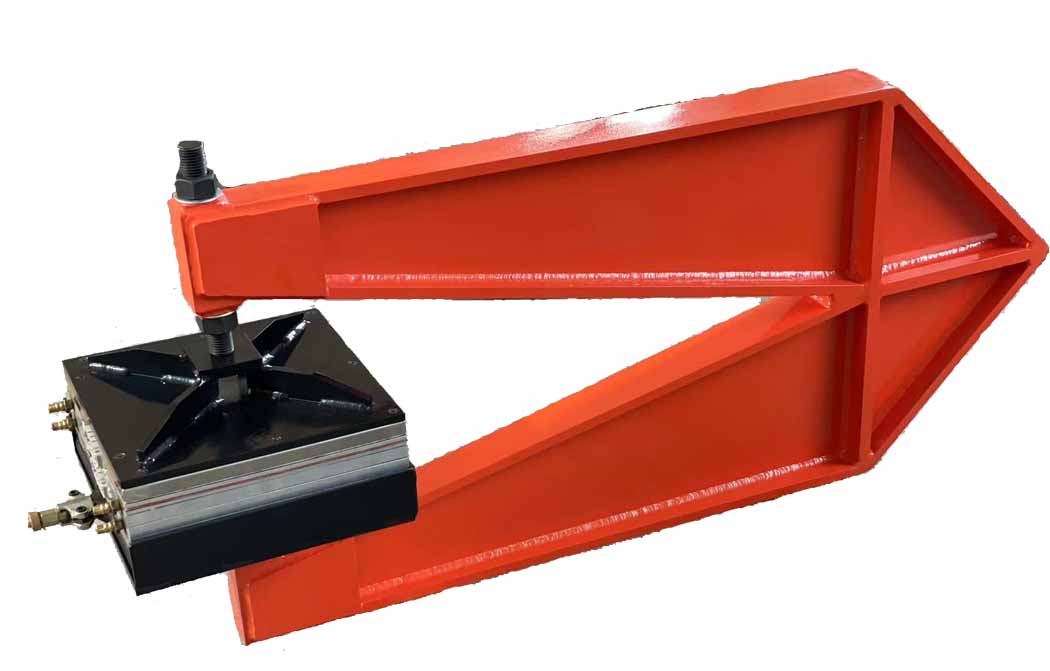

After use, it should be placed in a warehouse with air circulation, a relative humidity of not more than 85%, and not affected by rain. Sleepers should be placed under it, and it is strictly prohibited to place it on the ground. The vulcanization machine is generally composed of four parts: a clamping mechanism, a control system, a three pressure system, and a four heating system. The clamping mechanism is generally composed of a frame and bolts, the control system is composed of an electric control box and primary and secondary wires, the pressure system is composed of a water pressure plate and a pressure testing pump, and the heating system is composed of a heating plate and an insulation plate.

Working principle: Rubber belt vulcanization is a process of changing from raw rubber to mature rubber, in which a vulcanization machine is required to provide pressure, temperature, and control vulcanization time. The vulcanization machine meets this process, with the frame and water pressure plate providing pressure, and the electric control box and heating plate providing temperature and controlling vulcanization time. Generally, the vulcanization temperature of ordinary rubber belts in China is 145 degrees Celsius, and the vulcanization pressure does not exceed 1.5 MPa. The vulcanization time varies from 30 to 60 minutes depending on the tape.

Before using the conveyor belt vulcanizing machine, the insulation resistance of the hot plate should be checked. If it is too low, it should be dried with electricity first until the insulation value reaches below 50MPa before use. During the use and transportation process, it should be handled with care and handled in a civilized manner. If working in the field, reliable rainproof and waterproof measures are required to avoid being affected by rain and moisture.

After use, it should be placed in a warehouse with air circulation, a relative humidity of not more than 85%, and not affected by rain. Sleepers should be placed under it, and it is strictly prohibited to place it on the ground. The vulcanization machine is generally composed of four parts: a clamping mechanism, a control system, a three pressure system, and a four heating system. The clamping mechanism is generally composed of a frame and bolts, the control system is composed of an electric control box and primary and secondary wires, the pressure system is composed of a water pressure plate and a pressure testing pump, and the heating system is composed of a heating plate and an insulation plate.

Working principle: Rubber belt vulcanization is a process of changing from raw rubber to mature rubber, in which a vulcanization machine is required to provide pressure, temperature, and control vulcanization time. The vulcanization machine meets this process, with the frame and water pressure plate providing pressure, and the electric control box and heating plate providing temperature and controlling vulcanization time. Generally, the vulcanization temperature of ordinary rubber belts in China is 145 degrees Celsius, and the vulcanization pressure does not exceed 1.5 MPa. The vulcanization time varies from 30 to 60 minutes depending on the tape.

英语

英语 英语

英语