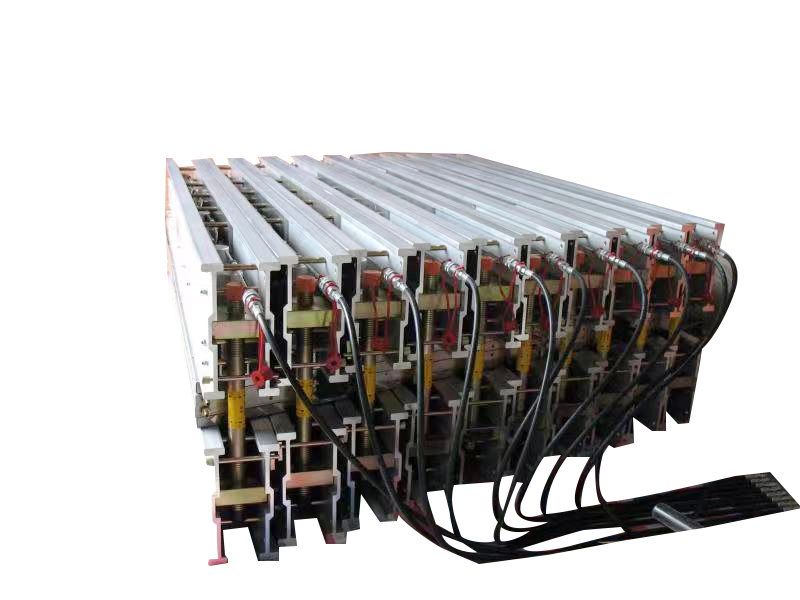

Conveyor belt vulcanizers-Vulcanizing press

Heating method of heating plate for conveyor belt vulcanization machine

The temperature, pressure, and time during the vulcanization process are the three elements of its vulcanization, and accurate control of these three elements is the key to determining product quality. Whether the vulcanization pressure is constant depends on the hydraulic station and is guaranteed by specialized equipment; The vulcanization time is generally easy to accurately control; Relatively difficult to control is the vulcanization temperature, which is the hot plate temperature.

Before operation, check if the oil tank has reached the required scale, and then turn on the machine to check if all components are working properly and if the column is lubricated. When preheating, pay attention to the temperature of the hot plate. If the request is not met, it must be adjusted under the guidance of the guidance of the instructor. Unauthorized movement is prohibited. When placing the mold in the hot plate room, it should be avoided from scalding or crushing the end, and it should not be placed in the mold when the hot plate is rising.

After the mold is loaded, the center of the flat plate should be placed and people should stand in the center of the operating platform. Use an iron hook to remove the mold to avoid crushing your hands. When encountering finished products sticking to the mold during mold opening, be careful when tapping the mold opening object to avoid hitting the mold or injuring your feet. If there is a problem with the machine, it is necessary to immediately cut off the power supply and state to the teacher that unauthorized disassembly of various components is prohibited. Crush the mold and prohibit unauthorized handling.

After the experiment is completed, cut off the power supply, clean up, and fill in the usage record. The density of goods is high, and iron pollution is minimal. The structure is novel and common, simple and reasonable, and operates smoothly. During production and operation, stones can form a protective layer, and the body is wear-resistant and durable. After non crushing, the material has strong ability and is less affected by the moisture content of the material, resulting in high moisture content. The main bearing is circularly lubricated by a thin oil station, and there is a standby oil pump to ensure continuous oil supply to the main engine, which can realize automatic control and incident alarm.

英语

英语 英语

英语